Choosing the Best Bandsaw blades Online in India – BansalTone

Are you a new bandsaw blade owner? The blade supplied on your machine won't last forever, so eventually you may have to take the plunge and get a brand new bandsaw blade. To avoid wasting your time and money, take a glance through this guide and make the correct choice at the very first time.

Manufactured by the leading Japanese Tool brand, TONE, using advanced CNC machining and specialized heat treatment, BansalTone offers a good range of high-quality bandsaw blades online in India designed to fulfill all requirements.

Length

The most obvious piece of data you wish to grasp is “how long is my Bandsaw blade?” this could air the spec label on your machine, or within the reference. If you've got neither, please reach out to BansalTone for advice.

Width

Secondly, you would like to decide on the width of the metal cutting bandsaw blade. Always use the widest blade possible – it's stronger and can withstand greater feed pressures without flexing. Consult your machine manual for the most and minimum blade widths that it'll accept.

If you're a Carpenter, cutting bowl blanks with a bandsaw blade is both safe and effective. However, you must choose a bandsaw blade that may cut the radius you wish.

The minimum specifications for every TONE Bandsaw blades are as follows:

And, don’t forget. A bandsaw blade used for a batch of cutting wood planks won't be much use for metal cutting. Cutting curves will disturb the set of the teeth on the Bandsaw blade, consequently making it impossible to chop during a line. So we advise you to use your metal cutting bandsaw blades for cutting metals.

We have a specialist Nachi Make Bi-Metal Bandsaw Blade in our online store.

Tooth form & pitch

The third area to contemplate is tooth form and pitch. This may rely on the kind of labor you plan to do, i.e. rip cutting (with the grain) or cross cutting (across the grain). Generally, a bandsaw blade is employed even for rip cutting, whereas a regular metal cutting Bandsaw blade is used for cutting ferrous objects.

The skip tooth is provided on coarse tooth bandsaw blades, those with 2/3, 3/4 and 6/10 teeth per inch; it's a good shallow gullet with lots of space for waste to gather. Please note that the standard of the cut may be adversely tormented by sawdust packing between the teeth.

2/3 TPI

Used for deep cutting especially rip cuts. This bandsaw blade will leave a rough sawn finish although slow feed rate and high tension will improve the finish of the cut.

4/6 TPI

Good for general-purpose use with a degree of cutting across the grain and with the grain. An inexpensive finish will be achieved with slower feed rates and good tension.

6/10 TPI

The ideal general purpose bandsaw blade suitable for cross cutting up to 150mm and ripping in sections up to 50mm thick, although thicker sections may be cut using slow feed.

The regular, or triangular, tooth form is provided on bandsaw blades with 10 or more teeth per inch where, thanks to the reduced material removal, there's less need for waste storage.

8/12 TPI

Good for cutting plywood and MDF additionally ferrous metals and plastics. The finish is nice when cutting natural timbers, but the feed rate of the bandsaw blade should be slow and maximum depth of cut mustn't exceed 50mm. When cutting metals, you should reduce the speed of the metal cutting bandsaw blade in the maximum amount as possible, especially when cutting ferrous metals or forged iron.

Types

High steel bandsaw blades are often referred to as “Standard Blades”. Standard blades are best described as general purpose and are suited all those normal tasks within the workshop where a smooth, good quality, ‘no fuss’ performance is required, day in and day trip. We have a specialist Nachi Make Bi-Metal Bandsaw Blade in our online store.

Nachi Make Bi Metal Bandsaw Blades

Our Nachi Make Bi Metal Bandsaw Blades are the unique Ground Tooth (GT) design. This newly developed material is meant for the assembly user with high feed rates of cutting and is ideally suited to the rigors of running on two wheels. The diamond ground teeth are so unbelievably sharp (they stay sharper for a minimum of 30% longer) that the metal cutting bandsaw blades work extremely well altogether materials giving an exceptionally prime quality finish and clean cut. The GT range is meant for general purpose board and cross grain cutting work.

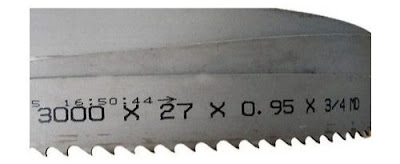

Specifically intended for wood processing and deep ripping tasks, fitting some larger machines where motors of sufficient capacity are able to handle the 27 mm wide bandsaw blade. The teeth are precision ground using CNC machinery and so induction hardened. Furthermore, to make sure a really long working life, each bandsaw blade are often re-sharpened up to twenty times, offering the most effective possible cutting performance.

To Buy Bandsaw blade Online in India,

Click here: https://www.bansaltone.com/product-category/other-products/bandsaw-blade/

Comments

Post a Comment